Cutting plotters are revolutionizing the world of design and production. Whether you’re into crafting, business graphics, or large-scale manufacturing, understanding how these machines work and choosing the right one for your needs is essential. In this guide, we’ll dive deep into the fascinating world of cutting plotters, breaking down everything from their functionalities to tips on selecting the ideal plotter cutting machine.

Cutting plotters have become essential tools in various industries, from graphic design to textile manufacturing. These machines, also known as plotter cutting machines, are used to cut materials like vinyl, paper, and fabric with high precision. But what makes them stand out from other cutting tools?

A cutting plotter operates with incredible accuracy, allowing for complex designs and patterns to be cut with minimal waste. This efficiency is crucial for businesses that require precise, high-quality outputs. If you’ve ever wondered how intricate designs are cut so perfectly, a cutting plotter is often the answer.

Defining a Cutting Plotter?

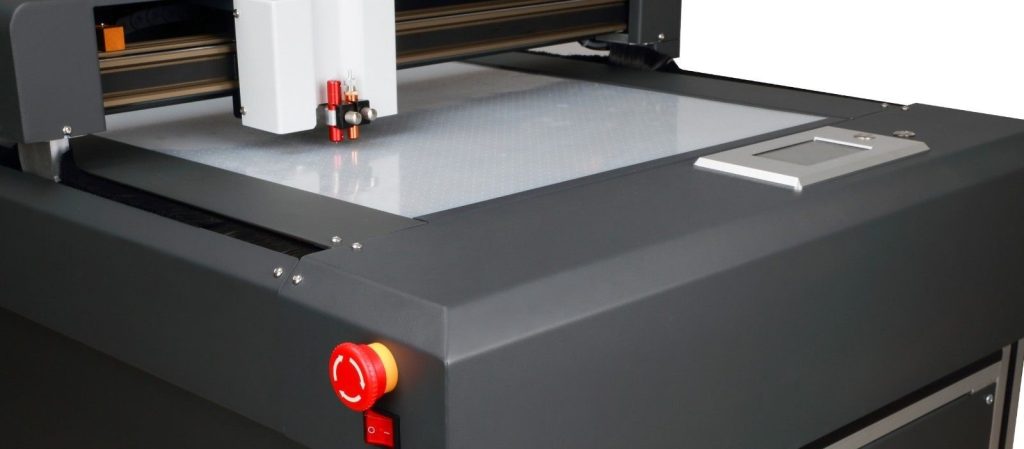

At its core, a cutting plotter is a device that uses a blade to cut materials according to a digital design. It operates similarly to a printer but instead of ink, it uses a blade to cut out shapes. The design is created on a computer and then sent to the plotter, which cuts the design onto the chosen material.

Cutting plotters are essential for businesses that need to produce consistent, high-quality cuts for various applications. From custom stickers to intricate vinyl designs, these machines offer versatility and precision.

How Does a Cutting Plotter Work?

Understanding how a cutting plotter works can help you appreciate its functionality and make an informed choice when purchasing one. The process involves several key steps:

- Design Creation: First, you create a digital design using software. This design is then converted into a format that the plotter can read.

- Material Loading: Next, you load the material onto the plotter. This could be vinyl, paper, or another material.

- Cutting Process: The plotter uses a blade to cut the material according to the design. The blade moves along the material, following the paths defined by your digital design.

The precision of a cutting plotter ensures that every cut is exact, which is vital for applications requiring intricate detailing.

How to Set Up and Use a Plotter Cutting Machine

Setting up a Plotter Cutting Machine involves several steps to ensure proper operation. Begin by unpacking the machine and placing it on a stable surface. Plug the machine and make sure all the cables are properly connected.

Next, install the cutting blade and configure the machine settings according to the manufacturer’s instructions. Calibrate the machine to ensure accurate cuts and test the setup with a sample material. By following these steps, you can ensure that your plotter cutting machine is ready for use.

Tips for its Effective Use and Maintenance

To achieve optimal performance from your Plotter Cutting Machine, it’s important to follow best practices for use and maintenance. Keep the machine clean and inspect it regularly for any signs of wear or damage. Ensure that the cutting blade is sharp and properly aligned to maintain cutting precision.

Additionally, keep the machine’s software updated to benefit from the latest features and improvements. By adhering to these tips, you can extend the lifespan of your plotter cutting machine and ensure consistent, high-quality results.

Choosing the Right Plotter Cutting Machine

Selecting the right plotter cutting machine involves considering several factors:

- Purpose and Applications: Determine what you’ll primarily use the plotter for. Different machines are better suited for different tasks, whether it’s for small crafts or large-scale production.

- Material Compatibility: Ensure the plotter can handle the materials you plan to use. Some plotters are designed for specific materials like vinyl, while others can cut a range of materials.

- Budget: Plotters come in various price ranges. Decide how much you’re willing to invest and look for a machine that offers the best features within your budget.

Assessing these factors will help you choose a plotter cutting machine that meets your needs and provides the best value.

The Rise of Mobile Plotters

Mobile plotters have gained popularity due to their portability and flexibility. These devices are designed for professionals who need to take their work on the go. They offer the same precision and capabilities as larger machines but in a more compact form.

Mobile plotters are particularly useful for events, trade shows, and other situations where you need to create custom designs on-site. Their convenience makes them a valuable tool for many professionals.

Maintaining Your Cutting Plotter

Proper maintenance is essential for ensuring your cutting plotter remains in good working condition:

- Regular Cleaning: Keep the plotter clean to prevent dust and debris from affecting its performance.

- Blade Replacement: Replace blades regularly to maintain cutting quality and avoid damage to the machine.

- Software Updates: Ensure your software is up-to-date for optimal performance and compatibility.

Following these maintenance tips will help extend the life of your plotter and keep it running smoothly.

Conclusion

Cutting plotters are powerful tools that offer precision, versatility, and efficiency for various applications. Whether you’re a hobbyist or a business owner, understanding how these machines work and selecting the right one can greatly enhance your projects. With the right cutting plotter, you can achieve high-quality results and streamline your production process.

FAQs

1. What is the difference between a cutting plotter and a vinyl cutter?

A cutting plotter is a broader term that includes vinyl cutters as a subset. Both tools cut materials, but a cutting plotter can handle a wider range of materials and more complex designs.

2. Can I use a cutting plotter for large-scale projects?

Yes, large format cutting plotters are designed specifically for big projects and can handle large materials.

3. How often should I replace the blade on my cutting plotter?

Blade replacement frequency depends on usage and material type. Regularly check the blade for signs of wear and replace it as needed.

4. Are mobile plotters as effective as larger machines?

Mobile plotters offer similar precision and capabilities but are designed for portability. They are ideal for on-the-go applications.

5. What materials can a cutting plotter handle?

Cutting plotters are capable of handling a range of materials, such as vinyl, paper, fabric, and more. Always check the machine’s specifications for material compatibility.