Are you tired of struggling with subpar cutting tools that just don’t deliver the precision you need? Enter Skycut Plotter Cutting Machines. These marvels of modern technology bring unmatched precision to your cutting projects. You might be crafting, designing, or working on industrial uses.

Skycut stands out in the crowded market of plotter cutting machines. Skycut has a reputation for reliability and innovation. Its machines are packed with features. These features are designed to make your cutting tasks easier and more efficient.

Do you know about the Plotter Cutting Machine?

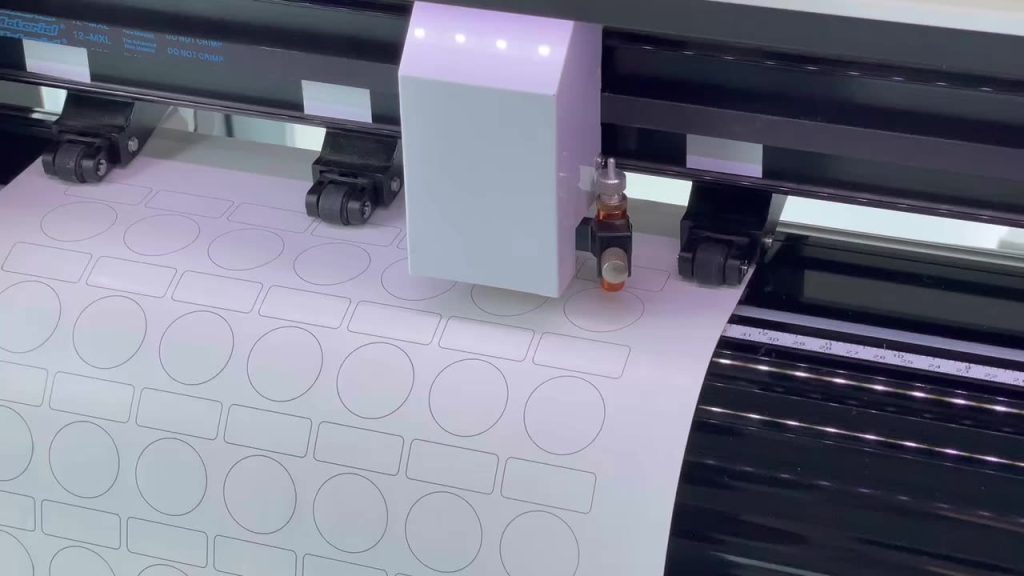

A plotter cutting machine is a device. It moves a blade, pen, or another tool across a surface to make precise designs, patterns, or cuts. These machines are essential in various industries, including sign-making, fashion, and graphic design.

- Precision and Efficiency

Skycut plotter cutting machines are designed to deliver precision and efficiency. Whether you’re working with vinyl, paper, or fabric, our machines ensure clean and accurate cuts every time. This not only saves material but also time, boosting your overall productivity.

- User-Friendly Interface

Our plotter cutters come equipped with an intuitive LCD interface. This makes it easy for users of all skill levels to use the machine. It reduces the learning curve and lets you start on your projects right away.

- Versatile Applications

Skycut plotter cutting machines are versatile. It works for crafts, sign-making, and fashion design and is adaptable to many uses. Its strong build and advanced features ensure it meets the demands of many industries. And it provides you with a reliable tool for your business.

What is Vinyl Cutting Plotters

Vinyl cutting plotters are complex machines. They are designed mainly to cut vinyl and other thin materials into precise shapes, intricate designs, or letters. They are vital tools in many industries. These include signage making, graphic design, crafting, and apparel decoration. They guide a sharp blade across material. They do this based on instructions from design software. This technology lets users make custom decals, stickers, and signs. It can create designs with exceptional accuracy and detail.

Magic of Vinyl Cutting Plotters

Vinyl cutting plotters exhibit remarkable versatility in handling a diverse array of materials:

- Adhesive Vinyl: Used extensively for crafting stickers, decals, and labels used in signage and branding.

- Heat Transfer Vinyl (HTV): Applied to fabrics to create personalized apparel, such as custom t-shirts or uniforms.

- Cardstock and Paper: Ideal for producing intricate paper crafts, scrapbooking elements, and detailed card designs.

- Craft Foils and Specialty Materials: Employed to incorporate metallic or textured effects into designs, adding a unique visual dimension.

Why Choose Vinyl Cutting Plotters?

The decision to opt for vinyl cutting plotters is supported by several compelling advantages:

- These machines are precise and accurate. They excel at cutting detailed designs with clean edges. They ensure professional-quality results.

- Vinyl cutting plotters are versatile. They can make small decals and large signs. They can be used for a wide range of creative tasks.

- Efficiency is the key. By automating cutting, these plotters save time. They beat manual cutting, which is slow. They also make output better.

- Users can customize products. They can design and make unique, personalized items. The items are tailored to their preferences and needs.

Understanding the Operational Process

- Design Creation: Users create or import their designs into graphic design software. There, they carefully prepare artwork for cutting.

- Software Setup: Once the design is done, it is put in the plotter’s software. Here, the design is turned into cutting instructions. These instructions tell the plotter where to move and put its blade.

- Cutting Process: The software guides the plotter’s blade. It follows cutting paths set in advance. It cuts the designs from the material with great precision.

- Weeding is the next step after cutting. It involves removing excess material. This material is called negative space or waste. It is from around the cut designs. This meticulous process is known as “weeding.”

.

Understanding the Cutting Plotter with LCD

What is a Cutting Plotter?

A cutting plotter is a computer-controlled machine. It precisely cuts materials like vinyl, paper, cardstock, and fabric. It operates like a printer. But, instead of printing, it uses a sharp blade to cut shapes and designs from digital patterns.

How Does it Work?

The cutting plotter reads digital designs made in design software. It uses its sharp blade to follow these designs on material on its cutting mat. The user controls this process with the LCD display. They use it to adjust size, shape, and cutting speed.

Evolution with LCD Display

The cutting plotter has an LCD display. It offers a more intuitive user interface than traditional models. The LCD screen provides real-time previews of designs and settings, allowing users to make adjustments directly on the machine without relying solely on computer software.

The inclusion of an LCD display transforms the design process into a more interactive and user-friendly experience. Users can visualize how their designs will look before cutting, minimizing errors and optimizing material usage.

Benefits of Using a Cutting Plotter with LCD

Precision Cutting

The primary advantage of a cutting plotter with an LCD display is its precision cutting capabilities. The machine can execute intricate designs with utmost accuracy, ensuring clean edges and detailed results that elevate the quality of your crafts.

Versatility in Material Handling

From vinyl to fabric and even thin wood sheets, the cutting plotter with LCD can handle a wide range of materials. This versatility expands the possibilities for creative projects, whether you’re making custom stickers, apparel designs, or home décor items.

Time Efficiency

With its automated cutting process and user-friendly interface, the cutting plotter with LCD streamlines production times. Tasks that would be labor-intensive and time-consuming manually are completed swiftly and efficiently with minimal effort.

Practical Applications in Crafting

One of the most popular uses of a cutting plotter with LCD is for creating vinyl decals and signage. Whether for personalizing gadgets or decorating spaces, the precision of the machine ensures professional-looking results that withstand time and wear.

Designing Fabric Patterns

Fashion designers and DIY fashion enthusiasts benefit greatly from the cutting plotter’s ability to cut fabric patterns accurately. This eliminates the need for manual tracing and cutting, saving time and ensuring consistency in every piece.

Creating Custom Cards and Invitations

For occasions that call for personalized touches, such as weddings or birthdays, the cutting plotter with LCD enables the creation of intricate card designs and invitations. This adds a unique charm that sets your event apart.

Skycut Plotter Cutting Machines revolutionize precision cutting with their advanced technology, catering to diverse industries from signage to fashion design. Offering efficiency, versatility, and user-friendly interfaces, Skycut ensures exceptional results in every project.